This post is sponsored by Ryder E-Commerce by Whiplash.

Ecommerce. It’s more than a buzzword or a fleeting trend. In today’s world, ecommerce plays a huge role in the ‘new normal’ – where customer satisfaction is at the forefront of every brand experience and shopping can be done virtually anywhere – without ever leaving the house.

Over the last five years, the ecommerce industry has grown from 10% of global retail sales to a whopping 20.4% – a huge jump for any business sector to make in such a small amount of time.

What does this growth mean for digitally native brands? The ecommerce fulfillment service space is getting increasingly competitive.

For brands to stand out from the crowd, they’ll need to not only meet customer expectations but go above and beyond to ensure the entire process – from browsing to checkout to unboxing – is completely seamless.

However, providing a flawless ecommerce experience is not as easy as it looks. It all boils down to this: behind every great ecommerce business is an even better order fulfillment strategy.

What Is Ecommerce Fulfillment?

Ecommerce fulfillment refers to the end-to-end process of storing, prepping, and delivering products to customers who purchase from an online store. This includes receiving and storing inventory within a warehouse space fulfillment center as well as picking, packing, and shipping.

Typically, online businesses work with a third-party fulfillment provider to define SOPs and service level agreements, ensuring the smoothest (and most efficient) order fulfillment experience for their customers.

How The Ecommerce Fulfillment Process Works: Step-by-Step

When it comes to an effective ecommerce order fulfillment process, there’s much more to it than what meets the eye. The best fulfillment services make it all happen so seamlessly that customers might not even realize how much work goes into getting online orders safely out the door.

This fulfillment guide breaks down the process for ecommerce sellers, covering the journey from sales, to fulfillment providers, and the services they offer. Welcome to ecommerce fulfillment 101!

Step 1: Inventory Is Received at the Fulfillment Warehouse

To sell products and fulfill orders, an e-commerce brand will first need to have inventory coming into either an in-house or outsourced space like a 3PL warehouse. Depending on where a brand’s suppliers are located, inventory travels via air or ocean before transferring to a truck for delivery to warehouses.

Brands will need to work with their suppliers to understand how their order fulfillment and deliveries will be managed to ensure the receiving process is as efficient as possible. For example, a truckload that has a floor-loaded shipment requires a different receiving workflow than one that is palletized.

Step 2: Inventory Is Organized, and Shopping Carts Are Integrated

The inventory is here – great! Now what?

Once products have safely made their way to a warehouse or fulfillment location, brands will need to store them efficiently and ensure their ecommerce platform or shopping cart is fully integrated.

Ideally, online businesses will have SOPs in place for inventory management, meaning their operations team will know all the necessary steps to properly label and enter stock into the system.

Utilizing a WMS or an OMS can help alleviate some of the manual work when it comes to picking and packing orders, ensuring the quickest turnaround time.

Step 3: An Order Is Received

Ideally, with a modern tech stack in place, an ecommerce company’s fulfillment team should have a real-time or close-to-real-time view of incoming orders.

This means that as soon as a customer places an order on an ecommerce website, it should be available for the operations team to begin working on.

Or, if there’s a gestation period in place for the order, it may sit until that period is over to ensure that there are no modifications before the team begins to pick and pack.

Step 4: The Order Is Picked and Packed

Once the order comes through and is ready to be prepared for the customer, the fulfillment team needs to ‘pick’ the necessary products and then ‘pack’ them for shipping.

Typically, warehouse staff will receive a pick list of items, whatever SKUs they need to gather and which pack station they need to be brought to. Depending on the size and quantity of products, ‘picking’ can happen manually or with the help of material handling equipment or robotics.

‘Packing’ is fully based on the brand requirements that are in place and usually includes a detailed workflow for operation associates to follow. For example, an order with branded packaging may have rules for which direction products face when placed within the box or additional marketing inserts to add on top.

Step 5: The Order Is Shipped to the End Customer

Finally, the order is all packed and ready to head out the door! The shipping workflow will depend on many factors, like whether a brand is working with order fulfillment companies, what carriers they’re utilizing, and what countries they ship to.

Typically, once orders are ready to be shipped out, the shipping label is printed and applied to the packages, and they’re handed off to a carrier like FedEx, DHL Ecommerce, or USPS for delivery.

If you work with a 3PL fulfillment center, they may have an established same-day shipping cut-off time; for example, orders must be received by 12:00 p.m. to be shipped out the same day.

Ecommerce Fulfillment Strategies

When it comes to the order fulfillment process, a brand can take various paths depending on their personal preferences. Ultimately, it’s up to the brand to decide which fulfillment model will work best with their ecommerce business. Let’s take a look at the popular models:

In-House Fulfillment

In-house fulfillment, also known as self-fulfillment, is an ecommerce model where brands manage all steps within the fulfillment process themselves.

This includes all the administrative tasks that come with order fulfillment, like hiring labor, managing schedules, leasing warehousing space, finding/sourcing packaging, and any other materials needed for packing an order.

While in-house fulfillment can be tempting for brands who want to have full control over their fulfillment process, it usually leads to higher order processing costs without the expertise of a 3PL who has negotiated carrier rates and is a pro at storing inventory efficiently.

In-house fulfillment works for:

Self-fulfillment works well for small businesses just getting started with a low volume of orders. It gives the team complete control over all aspects of the order fulfillment process and allows them to do some testing on what may or may not work for their customers rather than having everything set in stone with a 3PL.

The ability to pivot and try new things within ecommerce fulfillment is crucial for brands at any stage of their business.

Outsourced Fulfillment

The opposite of in-house fulfillment, outsourced fulfillment occurs when brands utilize a third-party fulfillment company to handle all order processes and develop a customized fulfillment solution.

Outsourcing fulfillment requires an online business to provide a plethora of information, such as historical volume data, product specs, value-added service SOPs, packaging requirements, and more.

Ultimately, the relationship between a third-party logistics company and an ecommerce brand should be more of a partnership, not a one-size-fits-all approach.

Outsourcing fulfillment might be intimidating for brands who are used to handling their own fulfillment services; however, the benefits are bar none. With an experienced ecommerce fulfillment provider, brands can provide a stellar fulfillment experience that has much less room for error.

Outsourced Fulfillment Works for:

Outsourcing fulfillment is best for brands in need of top-tier fulfillment software and inventory storage. This includes online retailers that are just beginning to scale quickly and haven’t been able to keep up with order volume as well as established retailers that have a complex product requiring plenty of handling care or specific packing.

Additionally, outsourcing fulfillment is an effective way to save money on high shipping costs. Once a brand partners with a 3PL, they can leverage the 3PL’s negotiated carrier rates, likely accessing pricing they might not have been able to get when self-fulfilling.

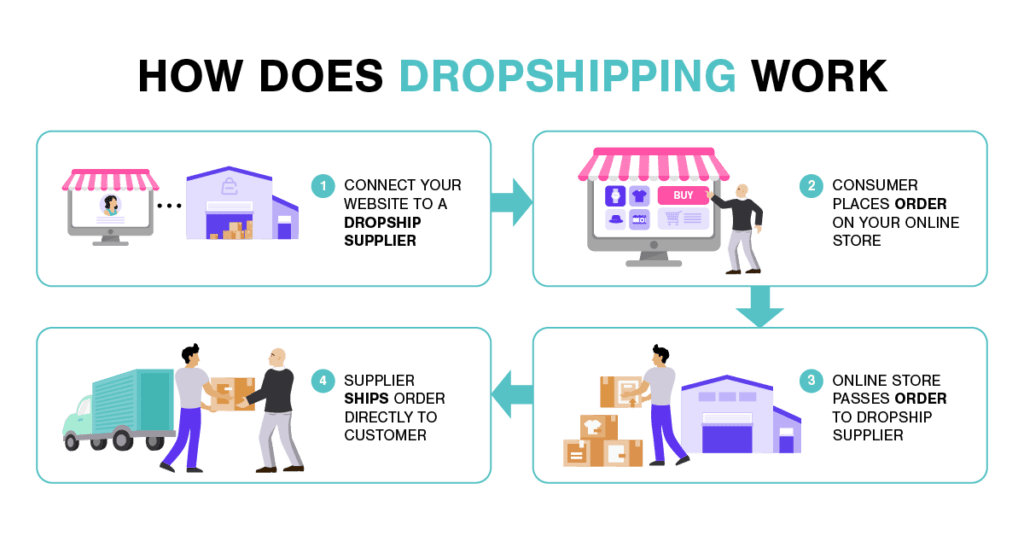

Dropshipping

Dropshipping involves merchants who don’t actually own or manage the inventory they’re selling. Instead, they work with a service provider, supplier, or manufacturer who completes order fulfillment.

The brand works as a middleman with the main goal of marketing the supplier’s product and encouraging purchases.

While it may sound like an unconventional approach to fulfillment, dropshipping is a safe and popular entry point for aspiring entrepreneurs. Plus, it’s expected to grow to a colossal 476.1 billion US dollars by 2026.

Dropshipping Works for:

There’s no inventory to purchase, no space or labor to manage, and no order fulfillment tasks to worry about. This means dropshipping works well for those who are most interested in facilitating sales rather than the behind-the-scenes processes of fulfillment services.

Amazon FBA

“Fulfillment by Amazon,” also known as FBA, is Amazon’s extensive fulfillment service options for its ecommerce brands. With FBA, sellers on Amazon can ship their products directly to Amazon fulfillment centers, where Amazon employees will pick, pack, and ship their orders out (and handle any return or exchange requests).

Ecommerce orders fulfilled through FBA are also eligible for Amazon Prime (hello, free two-day shipping!), making it an extremely attractive order fulfillment company for any retailer.

Amazon FBA Works for:

Because Amazon prioritizes high volume and turnover, FBA works best for ecommerce brands that are consistently selling products. Brands that have inventory sitting in the warehouse could rack up some pretty serious charges while using FBA’s services.

Additionally, Amazon leaves almost no room for a branded experience – packaging will include the Amazon logo – so brands who aren’t interested in providing that customized unboxing experience are more likely to do well with FBA.

What an Ecommerce Fulfillment Center Does

Now that we’ve taken a look at different ecommerce fulfillment models and the various steps that go into successfully prepping and shipping out an order, it’s time to take a closer look at all the services required for the most seamless experience.

Order Management

Once a customer clicks that “purchase” button, the order fulfillment journey begins. In order for this journey to be smooth and streamlined, some form of order management should be in place. Think of order management as the control tower – it’s the process of receiving, processing, tracking, and managing customer orders that come through various sales channels.

Vital to any ecommerce operation, order management allows brands to stay on top of every order that comes through their sales channels, avoid order errors, and (most importantly) save time and energy.

Inventory Management

Inventory management is the process of tracking all stock as they arrive at the warehouse and where they go from there. How? A system of labeling and tracking SKUs.

Effective inventory management is essential for successful ecommerce businesses, especially when it comes to order fulfillment, warehouse space, and tracking items. Without it, the probability of making mistakes spikes – and the list goes on and on: mis-picks, missed shipments, inventory shortage, damages, and more.

Brands partnering with a third-party fulfillment service should look for direct integration with their online store so that inventory levels are updated in real-time.

Picking and Packing

We’ve already touched upon pick and pack within the steps of order fulfillment – but there’s a lot of effort that goes into these seemingly mundane tasks.

Picking is more than just taking products to a different part of the warehouse. For the most efficient and time-saving method of picking, ecommerce businesses will need to develop optimized pick-routes or work with a 3PL that offers this fulfillment service to ensure no time is wasted when gathering inventory.

Similarly, packing is much more than putting products into a box! While it may add an additional workflow into the packing process, investing in fulfillment marketing allows brands to connect with their customers with a highly branded post-purchase experience.

Advanced Technology Integration

Today, successful ecommerce fulfillment is determined by whether or not your tech stack is up to speed. No longer are fulfillment centers relying on a massive workforce or huge amounts of space for a smooth operation; technology is the missing link between the front end of a fulfillment operation and the back end.

Think of it this way: Orders may be flowing into an ecommerce site and other online sales channels, but if they aren’t making their way to the fulfillment center to begin picking and packing, what’s the point?

Connected technology with infrastructure for order management, warehouse management, and inventory visibility will allow for a much smoother journey and a much happier customer.

Value-Added Services (VAS)

The best way to build a loyal base of customers is to provide excellent support. Adding value with every order. This can look like gift wrapping, specialized packaging, personalized notes, subscription boxes, return labels, and much, much more.

VAS as a fulfillment service is not just an “add-on” – it’s another opportunity to build genuine relationships with customers that will keep them coming back again and again.

Reverse Logistics, AKA Returns Processing

Returns. While the word may send a shiver up most merchants’ spines, reverse logistics is an inevitable part of the ecommerce journey. Whether customer expectations for color or sizing aren’t met, or it’s a case of defective products – returns happen.

The good news is that with some proactive workflows, returns don’t have to be scary, and they can actually boost customer retention. Working with a fulfillment provider who has expertise in reverse logistics can help streamline the process, reduce costs per return, identify trends, and recycle products that aren’t damaged.

Order Fulfillment Service: Where to Start

Location plays a huge role in the successful management of warehouses. If your fulfillment center is strategically located near your most loyal customer base, it leads to not only faster delivery but more cost-friendly shipping rates – both huge pros in the ecommerce buying journey.

Not sure where to look for a fulfillment center? Luckily, there are plenty of questions you can ask yourself to determine the most effective location, like “Where are my customers located?” and “What type of shipping options do I want to offer?”

Invest in Your Tech Stack

OMS, WMS, ERP… the technology available is almost endless for ecommerce fulfillment. From warehouse management systems and fulfillment software that track and optimize daily tasks to returns management tech that streamlines the reverse logistics journey – one thing is clear: effective order fulfillment is only as good as its technology.

Cloud-based logistics services are going to be your lifeline, so pay close attention to what you need to consider. First off, hunt for key features that relate directly to your needs. Is the app user-friendly? That’s a biggie. Then think about cost – the solution should be kind to your pocket as well.

But wait, there’s more. You want a solution that meshes well with your IT infrastructure and your other apps right? Of course, you do. And let’s not forget about security – that’s an absolute must. It needs to safeguard user data and ensure smooth sailing transactions.

So, as you walk down this path, keeping these considerations in mind will guide you towards the solution that fits you like a glove.

Develop Your Shipping Standard Operating Procedures (SOPs)

Depending on your ecommerce store and the types of products you’re shipping, your standard operating procedures will vary. This means that it’s incredibly important to develop unique shipping SOPs for your operation.

Will your brand use custom packaging? Are you shipping from multiple locations? Do you have multiple sales channels that require a different pack-out or carrier? Are you offering same-day or two-day shipping?

If your brand is working with a 3PL, you’ll need to ask yourself these questions (and more) to carefully analyze your shipping operation and needs. The best 3PLs will be able to ensure a cost-effective approach to picking, packing, and shipping.

Create a Return Policy

Did you know that over half of US consumers won’t shop with a merchant who isn’t offering free and easy returns? With returns being an unavoidable part of the business, ecommerce companies will need to make sure they have their return policy all figured out – before they get returns requests.

But, how?

- Outline what you offer for returns – like whether you give online credit or full refunds.

- Develop a standard for the condition of returned products.

- Decide what you’re going to do about shipping costs for returns.

- Clearly explain the returns process, step-by-step, to adequately answer customer questions.

Learn more about writing a returns policy here.

Partner with a 3PL

Ecommerce fulfillment is hard! With so many pieces moving at the same time – direct-to-consumer brands will need to make sure they’re staying on top of each and every aspect in order to meet customer demand for the utmost positive experience.

Partnering with a 3PL helps alleviate some of the pressure, putting the most complex parts of the ecommerce order cycle into the hands of a talented team of workers with expertise in fulfillment services.

What to Look for in a Fulfillment Service Partner

Perhaps the most important aspect of an excellent 3PL is its ability to grow with its brands. In today’s day and age, an ecommerce brand can scale to a size that historically took years to reach in just a few days.

With the right marketing and online presence, all it takes is a few viral posts and an invested community to boost the volume of shipments to the next level. When this happens, a best-in-class fulfillment company should be able to keep up with the newfound business growth – expanding storage space and labor to meet consumer demand.

Real-time Inventory Visibility

While inventory management will vary with each 3PL, some sort of system of real-time visibility must be in place for efficient ecommerce fulfillment. Not only should a fulfillment provider be able to mark and track individual SKUs, but they should also be able to filter inventory based on certain characteristics like level, location, orders, shipments, and selling channels.

The most successful ecommerce businesses stay in line with consumer behavior, patterns, and trends – all of which can fluctuate from hour to hour. Partnering with a 3PL that has accurate, up-to-the-minute inventory visibility and analytics data can help your brand avoid issues with low stock levels, excess inventory, dead stock, and split shipments.

Two-day Shipping Coverage

As the ecommerce space becomes increasingly saturated and more competitive, retailers need to continuously differentiate themselves from the rest of the pack.

Building customer loyalty is no longer based solely on products; it also depends on the relationships with people. Instead, there’s a mountain of factors that go into a customer’s decision to stay with your brand or not, all revolving around the complete customer experience.

One of the most important factors? Shipping time. Because consumer demand for quick and easy shipping is at an all-time high, shipping speed has become somewhat of an extension of an ecommerce business’s customer experience.

If your fulfillment options are too long, especially during the holiday season, your customers will likely abandon the cart and shop elsewhere. This makes it all the more important to find a 3PL that can confidently offer two-day shipping.

Multiple Fulfillment and Distribution Centers

Instead of having one single fulfillment center or warehouse, brands can opt for a multi-node fulfillment approach, which includes utilizing multiple fulfillment center locations based on consumer demand as well as proximity to transportation hubs or parcel carrier services.

3PLs who have fulfillment centers strategically located across the US should be able to provide this sort of approach (when it makes the most sense).

When done properly, shipping orders from more than one fulfillment center can actually decrease fulfillment costs, get products to customers faster, and lower the overall carbon footprint of an order.

Streamlined Technology Integrations

Technology is the end-all/be-all of online shopping. So, it makes sense that tech integration is a must-have in the ecommerce space. Brands looking to outsource their fulfillment will need to ensure their 3PL has a technology focus that optimizes and streamlines their fulfillment services.

For example, an ecommerce brand using Shopify to power its online site will want to look for 3PLs with a Shopify integration for a two-way order sync. Similarly, a brand looking for plug-and-play integrations will want to ensure their 3PL offers these types of partnerships as well as open API for in-house developers.

Ultimately, if a 3PL is not embracing new technology, it’s likely they don’t have a forward-thinking mindset. Instead, they could be unintentionally slowing the growth of their customers.

FAQs

What are the steps of ecommerce fulfillment?

Ecommerce fulfillment refers to the process of receiving and processing orders, picking, packing, and shipping products to customers. The steps involved in ecommerce fulfillment typically include:

1. Receiving and processing orders

2. Picking products

3. Packing products

4. Labeling products

5. Shipping products

6. Tracking and managing shipments

Understanding ecommerce fulfillment will help you decide on the best fulfillment provider for your company or if there is a fulfillment method you might be able to establish internally. The most important thing is for your order fulfillment platform to be efficient, accurate, and scalable with your business in the cloud.

What is meant by EC order fulfillment?

EC order fulfillment refers to ecommerce business order fulfillment. It involves receiving orders placed online, processing the orders, and delivering products to customers. This can be handled by the company itself or an external ecommerce fulfillment company like ShipBob. Order fulfillment services can take care of all of the shipping and fulfillment for ecommerce companies through their pre-established fulfillment network.

What are the different types of ecommerce fulfillment?

In-house fulfillment, 3PL, and dropshipping are the three main types of ecommerce fulfillment strategy. ShipBob and fulfillment by Amazon are two examples of outsourced fulfillment companies offering 3PL services such as packing and shipping. The business size, type of merchandise, and preferred fulfillment methods will determine which option will best benefit ecommerce merchants. With a solid business plan and understanding of ecommerce best practices, any seller can turn a profit.

Fulfillment Logistics: A Short Summary

Phew, there’s a lot that goes into ecommerce fulfillment, huh?

While supply chain woes have made their way into mainstream media and conversation, many consumers still don’t fully understand the ins and outs of the fulfillment process. In fact, they’re mostly concerned with getting their product quickly, undamaged, and perhaps with a touch of personalization.

It can be beneficial to keep customers somewhat in the dark about ecommerce fulfillment services, making the end goal of a safely delivered package all the more ‘magical.’

That being said, ecommerce stores will need to delve even deeper into the details of it all if they want to streamline their order fulfillment and keep their customer satisfaction levels in the green.

While there isn’t a secret sauce to ‘perfect’ order fulfillment – there is a way to stay ahead of the game. It involves taking a long, hard look at your ecommerce business, your entire fulfillment and shipping process, your tech stack, and your fulfillment partner. The goal? To understand each and every opportunity for a sterling order fulfillment journey.